Application Area

In modern factories, automation and semi-automation are becoming more and more common, and when people and machines work together, on some potentially dangerous mechanical equipment, such as punch machines, bending machines, injection molding machines, balers, automated assembly lines, automated Welding lines, mechanical transmission and handling equipment, etc., can easily cause personal injury to workers.

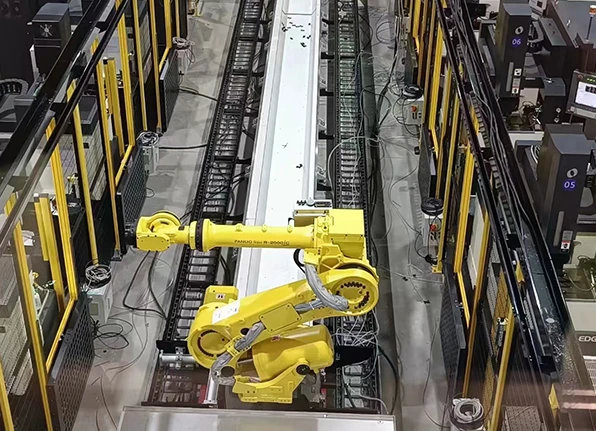

Automated production line

In automated production lines, safety light curtains are usually used to prevent people from approaching dangerous areas, provide safety protection when machines are running, prevent failures during object transmission, and protect operators from dangerous objects. It has the characteristics of high sensitivity, high reliability and fast response, which can ensure the safety during the operation of the production line.

Punch machinery

Punch machinery usually works at high speed and high pressure. The use of safety light curtains can effectively avoid the problems of cumbersome operation and low production efficiency that may be caused by contact safety devices. The safety light curtain has the characteristics of high sensitivity and quick response, which can promptly detect the operator or other objects entering the dangerous area and quickly stop the operation of the punch machine to ensure the safety of the operator.

Bending machine

Bending machines usually work under high pressure. The use of safety light curtains can ensure the safety of operators, improve the working efficiency of the bending machine, and reduce the risk of machine failure. The use of these technologies can improve the working efficiency of the bending machine, reduce the risk of accidents, and provide real-time data and intelligent support for the operation and maintenance of the bending machine.

Injection molding machine

The application of sensors in the field of injection molding machines can monitor and control key parameters in the injection molding process in real time, improving work efficiency and product quality. The safety light curtain ensures the safety of the operator and stops the machine in time when a person is found approaching the dangerous area. The application of these technologies can improve the safety and production efficiency of injection molding machines and reduce the occurrence of production accidents and quality problems.

Baler

In the field of balers, sensors and safety light curtains also play an important role. Sensors can provide real-time data feedback for operators to monitor and adjust the working parameters of the baler. By adjusting parameters in time, the efficiency and quality of packaging can be improved, and the life of the equipment can be extended. Safety light curtains monitor the operating area of the baler by emitting and receiving light beams. When a person or object enters the dangerous area, the light curtain will immediately send out a signal to stop the operation of the baler to ensure the safety of workers. Safety light curtains have fast response and accurate detection capabilities, which can effectively prevent accidents.

Send An Inquiry

GET IN TOUCH NOW

×